DIECAST FORCE

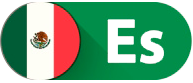

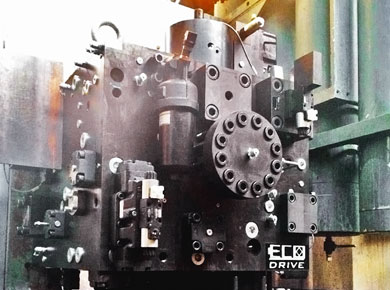

Diecast machines are some of the highest stressed machines in the industry.

Related to this the fails of diecast equipment are multifarious.

Without really expert technology the differences between request and result will be higher by time.

All solutions for problems have to be highly approved and solidly built.

We do have a 25 year experience in diecast and know to appreciate the usual solutions.

For special needs we are able to develop custom-designed adaptions.